Description of the Project[]

X-treme Garments is about the creation of a garment which helps keep the user at a constant temperature under as many environmental conditions as possible. After all, the human body only works optimally within a small range of temperatures. High temperatures may impair judgement, while cold temperatures may reduce the body's physical functions.

This garment is envisioned as a skin tight suit, capable of fitting into any situation. As such, many improvements can be integrated later on, such as communication and fashionistic designs, rahter than being a standalone garment that only has a fixed set of applications.

Existing Inventions[]

Passive vs. Active Temperature Changing[]

Passive warming has been around for quite some time, in the form of jackets. Likewise, passive cooling has also been around for a long time, and is used especially in sports and first aid treatment. The easiest method would be to place ice in a bag and put in on the required area. Some more complex creations include jackets with special gel material in them that help to slow down the speed at which it becomes warm. These jackets are placed in refrigerators to cool them down before use.

Passive cooling, however, is not very practical in some situations as it needs to be prepared beforehand. With active cooling and heating, temperature change of the body can be achieved on demand. Additionally, the user will be able to control the rate of temperature change. However, active cooling is not without its drawbacks, such as the requirement of a power source to circulate the cooling agent, or the need to research a method to cool down the cooling agent.

Current Designs[]

A jacket with in-built fans, also known as the air-conditioned jacket , has already been created in Japan, thus solving some of the heat and cold problems faced by the people there (Hannah, 2011). This is a low power system, thus it only requires two AA batteries to operate.

Another design is the Cool Shirt by Shafer Enterprises. With its patented tubing design that is sewn onto an undershirt, it cools people down by passing cold water through the tube.

Limitations of the Air-Conditioned Jacket[]

The jacket with in-built fans might be too bulky to carry around, and some people might not like it as the fan makes the whole jacket bulge when it is turned on – not a good image for fashionistas. Consisting of only computer cooling fans means that the technology can be easily replicated, this yields a lower barrier to entry into this market. Additionally, the technology has to be integrated into the desired outfit before it can be used. One company, Ronfell Groups , produces such air cooled jackets. From my resea

Air-con shirt

rch, they are able to put this technology into any garment a customer wants. This, however, is not practical as it involves some switching cost.

The jacket is also unable to stand up to extreme temperatures as it only relies on 2 fans to keep air moving into the jacket, which only allows for limited evaporation cooling. If the air outside is very hot (i.e. a desert), the fans would only be blowing hot air into the jacket, which is not very comfortable. On the other hand, if the environment was very cold, the cold air would be able to seep in through the holes of the fans, defeating the purpose of wearing the jacket in the first place.

Besides this, scientists have said that the jacket may not work properly in the heat and humidity of Singapore (Feng Zengkun, 21 July 2011 ). This would likely be due to the fans blowing air which is rich in humidity into the jacket, making any sweat from the user less likely to evaporate.

Limitations of the Cool Shirt[]

The cool shirt seems ingenious at first glance, having tubings that run cold water to dispel heat. However, what is being pushed to the side is the means of circulating the cold water. Using a small pump attached to a tub full of iced water, the shirt must be connected to this bulky equipment in order to function properly.

Cool Shirt

This technology is very much the same as that used in the Liquid Cooling and Ventilation Garment used in NASA's Space Shuttle Program. The bulky equipment, however, is of less importance than that of the Cool Shirt, since there is little to no gravity in space too weigh the equipment down. The Cool Shirt is able to cool down the users, but only when the shirts are attached to the pump. This means that it is not too useful in situations where the user is unable to carry the equipment with him/her, such as sports. To overcome that problem, the Cool Shirt has been marketed as a piece of equipment that allows a faster recovery time to dissipate the heat build-up.

However Cool Shirt loses the advantage when the user wishes for no recovery time, or the need to even recover in the first place, especially in situations where the user has an outer garment that would be too cumbersome to remove after putting it on.

The Human Body[]

The human body can only function properly between a small range of temperatures. As such, keeping the body at a constant temperature as much as possible is very important. To help in this matter, the body has some mechanisms.

For the human body, sweating is a method of releasing excess heat. No matter how uncomfortable, it feels, it is essential to the body. As such, people with a certain disorder of decreased sweating, also known as anhidrosis, are usually at a risk of overheating during exercise. Additionally, when a human feels emotions such as embarrassment and anger, sweat may be produced as a by-product since the sympathetic nervous system is connected to the sweat glands.

In cold environments, human bodies tend to shiver. This is to generate heat to keep the body warm. This, however, is a waste of energy and can be dangerous in extreme environments, since the body loses heat to the surroundings.

How the New Design Will Work[]

Heat and Sweat[]

Instead of relying on fans to evaporate body sweat, the new garment will be skin-tight, cooling down every surface it is in contact with. This prevention-rather-than-cure method will give users a more comfortable feel, much like snuggling into a warm bed on a cold winter night. Additionally, the new garment is able to keep users with anhidrosis cooler for a period of time before subjecting them to traditional treatments.

With regards to exercise and emotions, it will not be possible to prevent sweat from being produced, since the heat is being produced from within the body. However, the garment will be able to slow down the production of sweat by cooling down the body in the first place. Research by McLellan, Frim & Bell (1999) supports that heavy exercise in garment that build up body heat can be extended through the use of a liquid-cooled garment on the inside by up to 150%.

To help evaporate any accumulated sweat, the garment will integrate pores. These pores will soak up any sweat, and any wind that blows over the garment will cool it down, producing an evaporative cooling by-effect.

Cold Environments[]

Using the same system that cools the garment down, the garment can be heated up by reversing the current to produce reverse effects. The pores mentioned earlier will not stretch to the surface of the garment, producing small pockets of air that can be used as insulation.

How the Suit Will be Made[]

Conduction of Energy Throughout the Suit[]

A material with high thermal conductivity would be used to transfer heat uniformly throughout the whole suit. This would help reduce the situation where the cooling end of the pipe is colder than the rest of it, leading to situations where the user feels different temperatures at different spots.

Even though a material with high heat capacity would retain heat better, it would require more power to see the same amount of change in temperature. In light of this, a material with high heat capacity would be used to cover the whole suit and slow down temperature change in the suit. This would inadvertently lead to less power required to change the suit's temperature on the inside.

Changing the Temperature of the Suit[]

To change the temperature of the suit, parallel tubings will be laced through the suit. The parallel tubing design is chosen as a single tube will build up heat from the start to the end, lowering the net amount of heat it is able to dispel. The parallel tubings will be attached to a heat pump that will be minaturised. Using the heat pump, the suit will be able to pump the refrigerant as both a hot and cold liquid through the tubes.

The Heat Pump[]

The heat pump would have to be miniature in order to fit onto the suit. It will pump a form of refrigerant through the tubes, and based to the temperature the user wants, it would compress or expand the refrigerant. Basically it is a mini refrigerator that can go in reverse.

Methods to perform this function include the use of a reversing valve, thermoacoustics, and the vortex tube.

A heat pump was chosen due to the fact that it has the ability to pump heat in either direction, making it less messy than a system comprising of a set of cooling equipment and another set of heating equipment.

Other Cooling Methods[]

Evaporative cooling in conjunction with resistive wiring has been ruled out due to the need for a constant water source and its unsuitability in environments with high humidity. Laser cooling, while being high-tech, requires a laser to be trained on the suit and works mainly for atoms, and is thus impractical.

conventional Peltier junction vs thermotunneling chip

Thermo-tunnelling is somewhat like a Peltier junction. The only difference is that the electrodes are not connected together but are instead spaced a few nanometers away from each other, allowing electrons to tunnel from one electrode to another. This prevents the thermal energy from being transferred back to the cold electrode through conduction. Cool Chips is currently researching this area, but has yet to produce any commercially viable products.

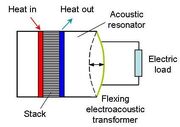

Thermoacoustics[]

Thermoacoustic tube

Thermoacoustics has been researched for some time. In fact, com/news/0416040003F.html Ben and Jerry's has sponsored the creation of a refrigerator that uses this technology to keep their famous ice cream cool. There are 2 main ways of using this technology for cooling. One is the use of stationary waves, which would require the use of a stack as shown in the picture to the right.

The other method is to use traveling waves, and the stack is exchanged for a metal foam regenerator. Both methods use sound to compress and expand a fluid, usually an inert gas. Using the laws of thermodynamics, compression produces a fliud of higher temperature, while expansion produces a fluid of lower temperature. The stack or regenerator seperates the cold and hot areas of the fluid. Heat exchangers are

thermoacoustic design 1

situated just in from of the stack or regenerator to extract or dispel heat. These heat exchangers are then stuck into the refrigerant tubings to transfer hot or cold refrigerant throughout the final product, just like in the figure to the right.

Another method of doing this would be to extend the other end of the tubing such that it runs through the suit, instead of having another tubing to run a refrigerant through. This would eliminate the need for heat exchangers, and only experimentation on the sound production to produce the required air would be needed.

The Reversing Valve[]

A key component in household heat pumps, it reverses the flow of the refrigerant to enable both heating and cooling. This component is a complex piece of equipment to install, and is currently available on the market as a piece of huge piping. The problems this equipment presents are the increased use of electricity required to power it, and its miniaturizing.

The Vortex Tube[]

The vortex tube works by pumping pressurized air into a vortex spin chamber. The air revolves to the hot end where some of the hot air is released. The remaining air is then forced backwards through the middle of the first vortex, passing its energy to the outer vortex as heat and finally exiting the cold end as cold air.

Vortex tube

Using a relocatable tube, users could plug the suit into either end of the vortex tube to recieve either heating or cooling. The main problem this design presents would be the generation of air with sufficient pressure to produce the necessary cooling or heating. The other problem of this design is that heating and chilling will not be able to be automated easily.

Alternative Design(s)[]

An alternative design would be to place Peltier junctions all over the suit. It fits the design requirements of being able to both generate heat and dispel heat. Additionally, being portable and tiny enough to be embedded into fabric, this would be a simple design to reach the design goals.

This is only put back by the fact that Peltier junctions are very inefficient and require a large power source to see a large change in temperature, making them reasonable to be placed in portable refrigerators. Tests will be conducted on Peltier junctions to determine if small power sources are able to produce a significant enough change in temperature of the suit.

Suit Fabric[]

Finally, the fabric would be made of Nike's Dri-FIT material. Additionally, the tight-fit suit will compress the user's body. A number of benefits have been derived from the use of compression suits, some of which include reducing body fatigue and chafing while increasing warmth, and also the reduction of decompression sickness at high altitudes. More tests will be conducted to see if this is really suitable or a better material should be found.

Future Work[]

I would require some tests to see how well the temperature changing of Peltier junctions would take place. In the case that the only option in using Peltier junctions is to research on how to decrease the size of the power source, I will turn to researching the other cooling methods, namely thermoacoustics, since producing a small source that has the ability to generate high power is something world class researchers are not yet able to achieve.

The use of solar power will be incorporated once the final prototype that runs on portable batteries is created, since it would be more prudent to make use of the surrounding energy to provide the power to change the temperature inside the suit.

References[]

Hannah, August 8, 2011, A Jacket with Built-in Fans In Sweltering Summer Heat of Japan, http://www.wupia.com/2011/08/a-jacket-with-built-in-fans-in-sweltering-summer-heat-of-japan/

Cool Shirt, http://www.coolshirt.net/

Ronfell Groups, http://www.airconjacket.com/about/index.html

Feng Zengkun, July 21, 2011, Air-con Jackets Don't Suit Our Climate, The Straits Times

McLellan T.M., Frim J., and Bell D.G. (1999). Efficacy of air and liquid cooling during light and heavy exercise while wearing NBC clothing. Aviat. Space Environ. Med., 70: 802-811. April 16, 2004, Turn it up to cool it down! This Earth Day, Ben & Jerry's introduces thermoacoustic refrigeration – an environmentally friendly way to chill out, http://www.worldwire.com/news/0416040003F.html , World Wire

Weekly Report, 20 September 2011[]

Sourcing of temperature detector[]

After looking through the temperature sensors available on the market, I feel that the suit requires an RTD (resistive temperature detector). This is due to the RTD having a higher accuracy. Additionally, the RTD does not require a terminal junction to be able to read the temperature, unlike the thermocouple. However, the RTD has a slow reaction time, and thus a thermocouple is required for immediate approximate temperature adjustment. The thermocouple, however, cannot be used without first calibrating the temperature. As such, a thermistor is required.

Sourcing of temperature dissipator[]

For the temperature dissipator, Copper is chosen due to its malleability, low heat capacity, and high thermal conductivity. Aluminium was ruled out due to its high heat capacity, even though it had a high thermal conductivity and was much more malleable.

Thermoreceptors in the human body[]

According to home science tools, the human body's thermoreceptors are stimulated between 5°C and 45°C, below which they stop working, and above which the pain receptors take over to prevent harm done to the tissues.

Results of tests for Peltier Junction[]

Current temperature of Junction = 22.8°C

Voltage/V Current/A Lowest Temp/°C Highest temp/°C

1.5 0.5 19.5 27.8

1.0 17.6 35.0

1.5 19.6 - 25.8 52.3

-------------------------------------------------------------------

3.0 0.5 19.4 28.0

1.0 17.5 35.1

1.5 19.8 - 26.0 52.3

Testing a peltier junction

Testing the peltier junction

Problems with Peltier Junctions[]

- Requires heat sink to dissipate heat, or else a change in temperature of lower than 2°C is not possible, since the heat is dissipated back to the cold side from the hot side through conduction.

- Expensive to create a whole flexible suit of peltier junctions.

- Not stable, unable to give a specific temperature for a given current, since the temperature change is dependent on the surrounding temperature.

Problems with Vortex Tubes[]

- Requires mechanical movement to change the outlet to whichever desired temperature.

- Requires an outlet for unwanted air--unable to be used in a totally enclosed environment.

- Requires a motor to drive pressurised air into tube.

- Requires more power underwater.

Problems with Thermoacoustics[]

- Might require motor to drive refrigerant.

- Non-commercialised technology--requires more testing and tweaking.

- Unsure if unwanted portion can just be insulated, or should be vented to atmosphere.

Weekly update, 28 September 2011[]

Latest project focus[]

My new focus in this project is to create a thermoacoustic tube prototype, and return some results on it. the thermoacoustic tube was decided on because it has more potential to be compact. It is also able to be more environmentally friendly than current cooling and heating systems, by not using CFCs.

Peltier junctions were ruled out since it was not feasible to place heat sinks all over the garment. Vortex tubes were not very useful if a protective garment of some sort had to be worn over the suit. Thus only thermoacoustics is feasible.

Calculations for materials[]

Calculation for fishing line diameter

calculations for tube length

Formulae were taken from Tabletop thermoacoustic refrigerator for demonstrations by Daniel A. Russell and Pontus Weibull, 29 May 2001 .

Weekly update, 8th October 2011[]

The first iteration of a thermoacoustic heat pump was created to test the characteristics of the technology. Results were however, unsatisfactory. More resources will be obtained.

making of stack

first iteration of the thermoacoustic heat pump tester

testing of temperature on cold end of stack

test of temperature at hot side of stack

This Page is created by: Seow Zhi Wei, U080256E Page now updated exclusively on http://xtremegarments.tumblr.com/